Bottle Labelling Machine

Bottle Labelling Machine

Brief Introduction :

High Speed Pressure Sensitive Labeling & Printing Capabilities.

- Wrap Around Pressure Sensitive

- Highest Quality, Lowest Price

- Panasonic Servo System

- High speed Lot, Expiry Date Printing

- Small to Large Size Bottles

Description of control system functions :

- A completely new type of intelligent micro-computerized servo labeling system recently developed by our company is used, the system can response quickly using automatic scanning and memory functions, free from input and setting, and it keeps a long time stable operation without crashing.

- Provided with imported factory installed human-computer interface, all the operating parameters and system information are shown on the screen, everything about the operation status is clear at a glance, so that the operator can eliminate any abnormality in time and enhance production efficiency, and its easy operability will reduce operators’ training time and save labor cost.

- The system’s audit function: the system can check out problems such as absence of labels, label ribbon breaking, label lost, emergency stop, frequency conversion abnormality, and lack of printer copying ribbon etc., and it will stop the system and send out alarms.

- This equipment has a labeling counter, label counting functions, and also has labeling speed displaying function. It not only can reduce unnecessary label losses and save cost, but also can facilitate the operators to control the production tempo and speed, so as to enhance production efficiency.

- I/O self-checking function: All the electric and light signals it can be displayed, and the motor operation can be independently controlled, so that the maintenance and repair time and cost is greatly reduced. It applies non-stage frequency control, when the conveying speed changes, labeling speed will be adjusted automatically, and there is no need to move the labeling magic eye along with it.

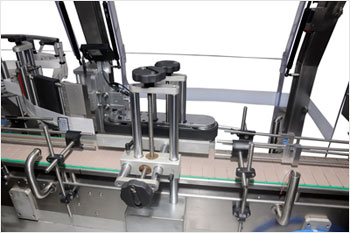

VML-760 High Speed Wrap Around Servo Labeling System :

Suitable for all types of small and medium round bottles at high speed, with high stability, and can meet customer needs for precision labeling that can reach to ±1 mm.

Machine Features :

Pressure Sensitive Wrap Around Labeling System

Labeling method: Pressure sensitive vertical wrap around labeling in the production line.

Suited product shapes: round bottles.

Suited product materials: plastic bottles, glass bottles, and metal bottles.

Product varieties suitable for labeling:

a. Foodstuff: drinks, canned food, healthcare products, and dairy products.

b. Pharmaceutical & Chemical: Powder, liquid, antibiotics (medicine bottles), syrups, pesticides, and animal remedies etc.

c. Household & Cosmetic products: cleaning products, spray products, maintenance products and cosmetics etc.

d. Industrial products: oil products, industrial chemical products.

Vertical bottle fixed position labeling machine :

Labeling method: Vertical wrap around labeling system with fixed position holding, specially designed for full or partial wrap around labeling with relatively high speed, accurate and efficient operation.

Suited product shapes: round bottles

Labeling Applications:

a. Food & Confectionary

b. Pharmaceutical & Nutriceutical

c. Chemical products d. Industrial products

Salient Features:

- Shorter change-over time

- Higher output

- Utmost simplicity in operation and maintenance

- Stainless steel cladding conforming to cGMP standards.

- Safety Guards

- Inter Locks

- User Friendly

- For small & large size bottles

Optional Features:

- Top labelling on cap

- Equipped with PLC control system and user-friendly touch screen control panel